The air compressor has a special shut off switch, which is integral to its functioning. It is programmed so that the flow of air is stopped when the pressure reaches a preset level, saving the motor from working too hard or running idle. The switch must be adjusted correctly in order for the air compressor to work as expected.

Before attempting to adjust the shut off switch on an air compressor, it is important to determine the make and model. This information can be gleaned from the compressor itself or its user manual, and once it has been established, it is a simple process to adjust the pressure switch accordingly.

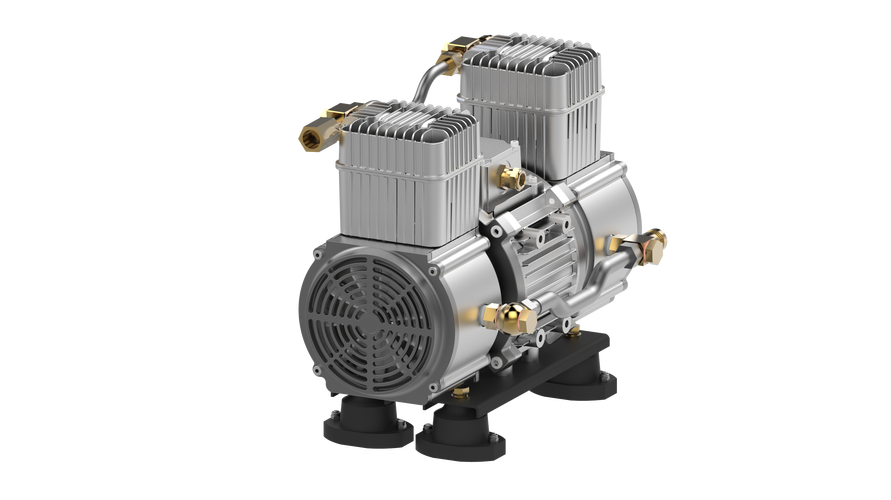

To properly identify the pressure switch, it is important to first know the model and make of the air compressor. After that, all that’s left is to locate the pressure switch, which can usually be found near the motor. It has a cylindrical shape and has two wires connected to it. This switch is labeled either as “Pressure Switch” or “Shut Off Switch”, allowing for an easier search.

To make sure the pressure switch is adjusted to the correct level, just take a look for the adjustment knob – it should be located on the side of the switch. All that needs to be done is to slowly turn this knob clockwise until it feels snug. This procedure is needed for the switch to be adjusted properly.

After the pressure switch has been tuned, the next move is to activate the air compressor. When the switch is properly calibrated, it will trigger the compressor at the desired pressure level. Sadly, if adjustments to the pressure switch don’t resolve the issue, then it will become necessary to acquire a replacement.

The air compressor shut-off switch plays an integral role in the system’s operation. If it isn’t correctly adjusted, it can create a host of complications, such as the compressor running unnecessarily or expending excessive energy in vain. It’s essential that the switch is set up correctly for the air compressor to work optimally.

Periodically, it is recommended to evaluate the air compressor shut off switch for correct adjustment. Doing this will support optimal operation from the air compressor and guarantee more secure operation. In the instance of having to substitute the switch, it is imperative to match the new one to the same model and brand as the old one.

All in all, the air compressor shut off switch is a critical component of its system. To ensure its optimal performance, this switch needs to be aptly calibrated. If replacement is required, make sure the new switch corresponds to the old one in make and model. Likewise, it is recommended to regularly inspect the pressure switch and guarantee that the air compressor is running orderly and securely.

The air compressor shut off switch performs a critical and necessary role in an air compressor system, with the responsibility of disconnecting the power from the compressor when it reaches a certain level of pressure. This protects the device from overpressure damage and saves energy by making sure it isn’t running for an unnecessarily prolonged period. Properly adjusting the switch should be one’s top priority in order to guarantee maximum effectiveness.

Before adjusting an air compressor shut off switch, it is imperative to take a moment and check for any signs of wear or damage. A thorough inspection can help guarantee that the switch is completely operational before any adjustments are made. If any wear and tear is detected, the switch should promptly be replaced with a new one.

After a thorough examination of the switch, it is essential to adjust the pressure settings accurately. Typically, the pressure can be adjusted via a knob or lever. Be sure to modify the pressure in accordance with the values specified either on the switch or in the compressor’s manual. Doing so will help to ensure that The switch operates at its optimal efficiency.

After tweaking the settings for pressure, it’s time to examine the switch’s operation. To ensure everything is in order, try powering the switch on and off a handful of occasions. It should always cut out at the previously determined pressure rating. However, if it does not, then additional adjustments may be needed.

Before concluding the job, one should verify the switch for any seepage. Start by detaching it from the compressor then switching it on and off a few times. Evidently, if a leak appears, patch it with a sealant or fetch a novel switch to swap instead.

Wrapping it up, the adjustment of an air compressor’s shut off switch is essential for its maintenance. Prior to tweaking it, examine the switch for any indications of wear or harm. Then follow up by making sure the pressure level is calibrated to the optimal amount and confirm correct operation. Lastly, seal any leaks or replace the switch altogether. Sticking to this process will ensure your air compressor is running smoothly and safely.

Related Product

Warning: Use of undefined constant rand - assumed 'rand' (this will throw an Error in a future version of PHP) in /www/wwwroot/www.sunritamachinery.com/wp-content/themes/msk5/single.php on line 69

11KW Mining Diesel Piston Air Compressor W1.8-5

Diesel Portable Piston Air Compressor Mobile for Jack Hammer / Mining1.Simple structure,light weight,easy to move .2.Easy operating and maintenance.3.High quality air delivery.4.Su […]

20KW Mining Diesel Piston Air Compressor 2V4.0-5

Double Air Tank Diesel Portable Best-Selling Engine Oil Piston Air Compressor are mainly used to supply stable and clean compressed air to the pneumatic tools and keep them working […]

S250 Air Leg Pneumatic Rock Drill Pusher Leg Rock Drill

Product description: (S250 jackleg Drill) has been the preferred choice of miners who demand high performance, superior control and lasting reliability. the S250 jackleg allows ope […]

B67C Pneumatic Chipping Hammer

Product description: The B67C crusher is made from Canada. Denver pneumatic Group company mature technology, with compressed air as a power crushing tool, can efficiently complete […]

RB777 Pneumatic Pick Air Shovel Cement Crusher Pneumatic Chipping Hammer

Product description: RB777 pneumatic picks are used to build roads, install works of broken concrete and other hardens Hard object tools, the machine structure is simple, high effi […]

TPB6 Air Concrete Breaker Pneumatic Pick

Product introduction: TPB-60 crusher adopts the mature technology of TOKU Group, Is compressed air as the power of the crushing tool, can efficiently complete the reinforced concre […]

TCD20 Pneumatic Pick Air Shovel Cement Crusher Pneumatic Chipping Hammer

Product description: The TCD-20 pneumatic pick is powered by compressed air using Japan’s TOKU technology Crushing tools, features: lightweight, small size, large strike ener […]

YT27 Air Leg Pneumatic Rock Drill

Short Description: The YT27 air-legged rock drill is a highly efficient lightweight rock drill suitable for downward or inclined drilling in medium-hard or hard (f=8 – 18) ro […]

YT28 Pusher Leg Rock Drill

Short Description: The YT28 air-leg rock drill is a kind of high-efficiency, energy-saving and environmentally friendly rock drilling equipment. Compared with similar pneumatic pro […]